Robots have fast become indispensable especially in manufacturing. It is almost impossible to find a manufacturing plant that does not use robots in their manufacturing processes. This is because they help to increase not only production volume but also improve quality.

Therefore, manufacturers of all sizes have adopted automation in many of their processes. It is especially crucial on assembly lines. Robot assembly has helped to simplify and speed up things on the assembly line.

These robots are used in material cutting applications. They are perfect for such tasks because they are:

- Flexible

- Highly repeatable

- Automated

- Reusable

In addition to these, they are low-maintenance and can be programmed to perform other tasks. Also, they boost weld strength and quality.

What Are Assembly Robots Used For?

Assembly line robots are of utmost importance on the assembly line. They help to:

- Give a huge boost to production

- Increase production speed

- Enhance consistency

These robots take over repetitive and mundane tasks thereby saving workers from monotony and exhaustion.

In a nutshell, robots make operations easier, faster and more cost-effective. End of arm tooling is customised to enhance efficiency and precision. Then other options such as vision also help to enhance product quality.

Assembly robots are versatile in that they can handle a horde of multiple deviations of a product. Also, it is easy to set up again should the product design change. Once the product line closes, you can recompose the assembly line and utilize the robots in other applications.

Robotic Assembly Applications

Cutting Applications

These include plasma, water-jet, laser and mechanical cutting. Cutting can be anything from the simple to the complex. For instance, a robotic water-jet cutter is utilized in cutting motor vehicle internal parts.

Material Forming

This is especially important for safety purposes. It is safer to use a robot for brake or tube banding than for a worker to do it manually. Manual applications may result in injuries. A robot can be programmed to load and unload without experiencing fatigue.

Welding Applications

A robotic welder will perform much better than a manual application. You can use one robot or several robot configurations depending on your need. Many manufacturers use a loading robot to position the material. Other robots can then do the welding.

Robotic welding helps to:

- Enhance weld quality

- Reduce wastage

- Diminish post-weld imperfections

- Decrease over welding

- Reduce gas consumption

- Reduce labour costs

- Lessen training expenditure

Robotic Gluing Applications

Speed is of the essence here. The robot operator controls the speed, as well as glue dispensing. The robot is programmed to dispense the same amount and quality of glue at any speed.

Some materials cannot be welded to each other. For instance, it is not easy to join aluminium to steel through welding. You can only achieve excellent results by using glue.

Also, you want to avoid wastage as much as possible as glue does not come cheap. A robot will dispense the precise amount of adhesive that is needed.

Painting

Painting can be a hazardous job as it can expose your employees to harmful carcinogens. It is also a dull, repetitive job. A robot paints with precision. This means that paint will be distributed evenly on all surfaces.

An automated painting system comes with features such as:

- Paint distribution equipment

- Paint handling

- Atomizers

It helps to reduce wastage as the robot uses a precise amount of paint. Additionally, it does not leave drips and the paint job is evenly spread out.

Inspection Tasks

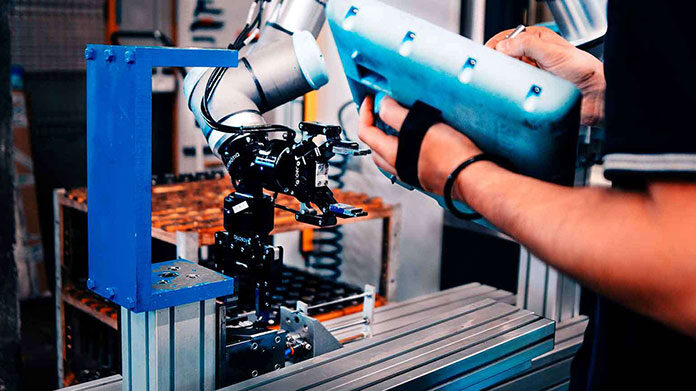

Once the material is complete, it needs to be inspected for errors. The robotic inspection system contains a camera that is mounted on the robot’s arm. The robot checks the material for flaws in assembly, painting and more. It also checks the parts for measurements and weight.

Conclusion

Robotic assembly is not only cost-effective but it also ensures product quality and production speed. You can economically automate your manual assembly applications to enhance productivity.